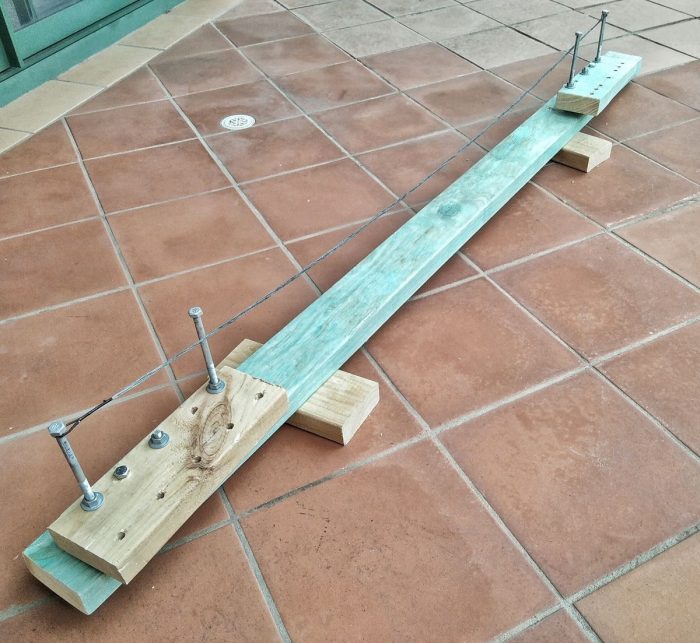

We know, these jigs are expensive, huge, and not easy for ordering and shipping to many places. There are some DIY solutions online. The hard part of them is, how to make a strong slot or heavy metal fixture to adjust the length smoothly, but it’s not quite necessary. Most of bowstrings are just integer number of inches, so, why not just drill integer inch holes on timber, and fix the poles on these positions?

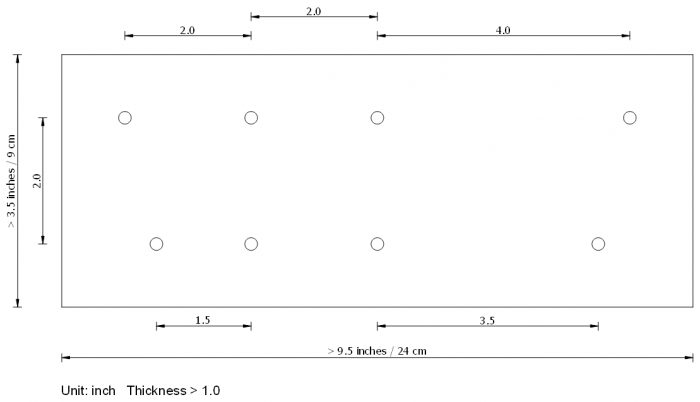

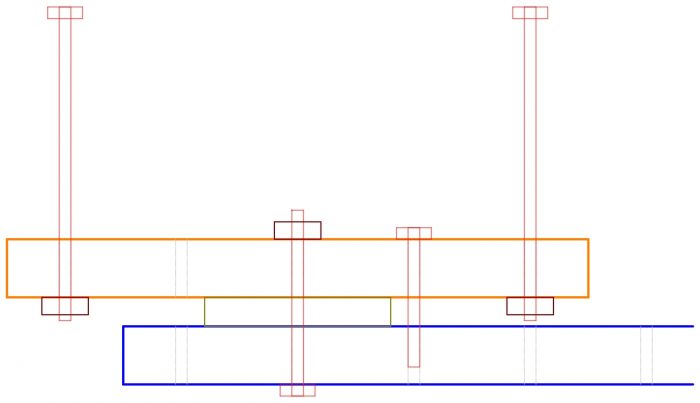

This is my idea that just needs timber, bolts, drill, and roughly saw cut. A row of holes with 2 inches distance on the base board, and the same 2 inches distance holes on the upper board that can fix the jig in horizonal and vertical direction.

There are two types of radiuses from the string pole to the axis on the upper board. One is 3.5 inches, for any odd number inches of string length (axis distance + 7 inches), the other is 4 inches, for any even number inches of string length (axis distance + 8 inches). If you need more precise length (e.g. 66.5 inches), just make another pair of upper board with the radius of 3.75 inches ( or just twist the string…)

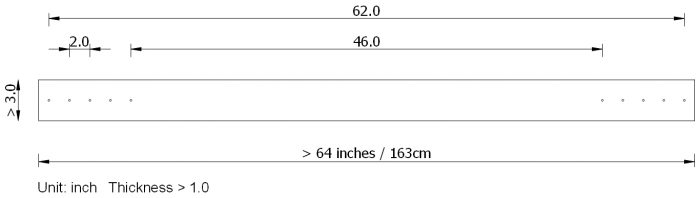

The base board. The shortest hole distance is 46 inches, and the longest is 62 inches. With the upper boards, the system can make bowstring from 54 to 70 inches. Of course, you can make a longer or shorter board as you need.

The upper boards need to be 3 inches wide at least because there are 2 rows of holes. The base board has just 1 row so it could be narrower. I bought a 2.4m long 90mm * 35mm timber (I’m in a metric country…) for the whole system.

I use M8 size drill and hex bolts for all the holes. M6 should be ok as well, but maybe not easy to buy long M6 bolts.

- Four pieces of 6 inches bolts as string poles, each one needs 2 sets of nuts and rings.

- Two pieces of 4 inches bolts as the main axis. The length depends on the thickness of the timber. Don’t be too long, so as not to interfere the string serving. One set of nuts and rings for each bolt.

- Two pieces of 3 inches bolts to fix the upper board on horizonal or vertical direction. The length depends on the thickness of the timber as well. No nuts or rings needed.

There should be around 1/4 inch space between the upper and the base board, thicker than a set of nut and ring, so the upper board can rotate with the nut of the string poles underneath. Use a thin board or several rings.

The Bottom of the base board is not flat as well, because of the head of the axis bolts. So put the rest of the timber under it.

Enjoy.

Leave a Reply